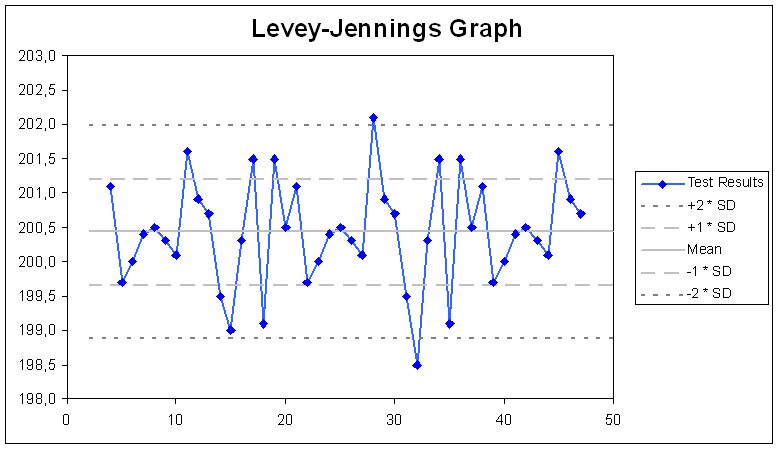

Let me take you to the internship days where we had just started working with the analysers in the laboratories. Even though we had read about Quality Control (QCs) and Quality Assurance (QA) in the last 3 years while completing our degree (medical laboratory science), it was really vague. QCs are really important in a medical laboratory. Now you might ask why? The routine QCs keep a check on the accuracy and precision of the test results produced by the laboratory. And how is that done? These QCs are plotted on a Levey Jennings (LJ) charts and are monitored according to the westgard rules.

What are quality controls?

Quality controls are either commercially/ manually made controls which have pre-decided values. The quality controls are run on the analyser at the beginning of the shift to rule out any assay variation that might interfere with the test results. They are at times run along with the patient sample, after running calibrations, after reagent lot change and when the analyser shows a QC error.

These control results are recorded and automatically plotted on the LJ charts by the analysers. To evaluate the accuracy of the results, they are evaluated using the westgard rules (read more: Westgard rules). For the QCs to be accepted they need to be within the +/- 2SD range. The value points outside 2SD above or below the mean are warning signals and should be taken in consideration.

Working with QCs in biochemistry department.

Even though I enjoy working in biochemistry, running QC is the most boring part of it. Every morning, the first thing expected of us is to conduct the scheduled maintenance on the analyser and run QCs. Even though different laboratories might use different analysers the QC principles remain constant.

But when to conduct a QC? This is a very common question. QCs for all the tests conducted by the labs are generally run at the start of the shift after the analyser maintenance. QCs are also run on the analyser after a conducting a reagent lot change, and after performing a calibration on a reagent pack.

After the QCs are run the results are recorded by the analyser and the data points collected are plotted on the levey jennings chart. Some labs might run the QCs before the samples are loaded on the analyser while other laboratories might run the QCs along with the patient samples depending on the urgency of the tests.

When the QC’s out of range?

On analysers like cobas series, AU5800 or DXIs which run a lot of different tests, the QC results are prone to systematic and random errors due various interferences. While working with the analysers we come across these situation very often in which the controls run out of range even when the analyser is working perfectly fine.

When this happens, we generally look back at the trend that the control is following. Is it running on a high or a low bias or are there any shifts or drifts. If there is a sudden drop or shift in a specific control it is rerun to rule out any random errors (determined if the control falls back in range). If the rerun QC also violates the westgard rules and falls out of 3SD range above or below the mean, the next few steps involves checking for the age of the controls and the reagent and discarding them if they have been in use for too long. This is done as the controls and reagents in use degrade with time and can be used until a certain period at when brought to room temperature. The expiry date of the reagents and the QC material is also checked and it is made sure that all the expired reagents and controls are dumped. It is also important to maintain the proper storage conditions for the QC material and proper handling (brining the QC material to room temperature for a short period of time) ensures that the controls do not deteriorate quickly. New QC material should be made up and used to eliminate this factor.

If the controls still falls out of range, finally it is troubleshooted by calibrating the reagent pack(/s). It is important to rerun the QCs after the calibration is finished and passed to verify that the analyser is producing accurate results.

Informative 10/10